Metalworking-machines applications and future

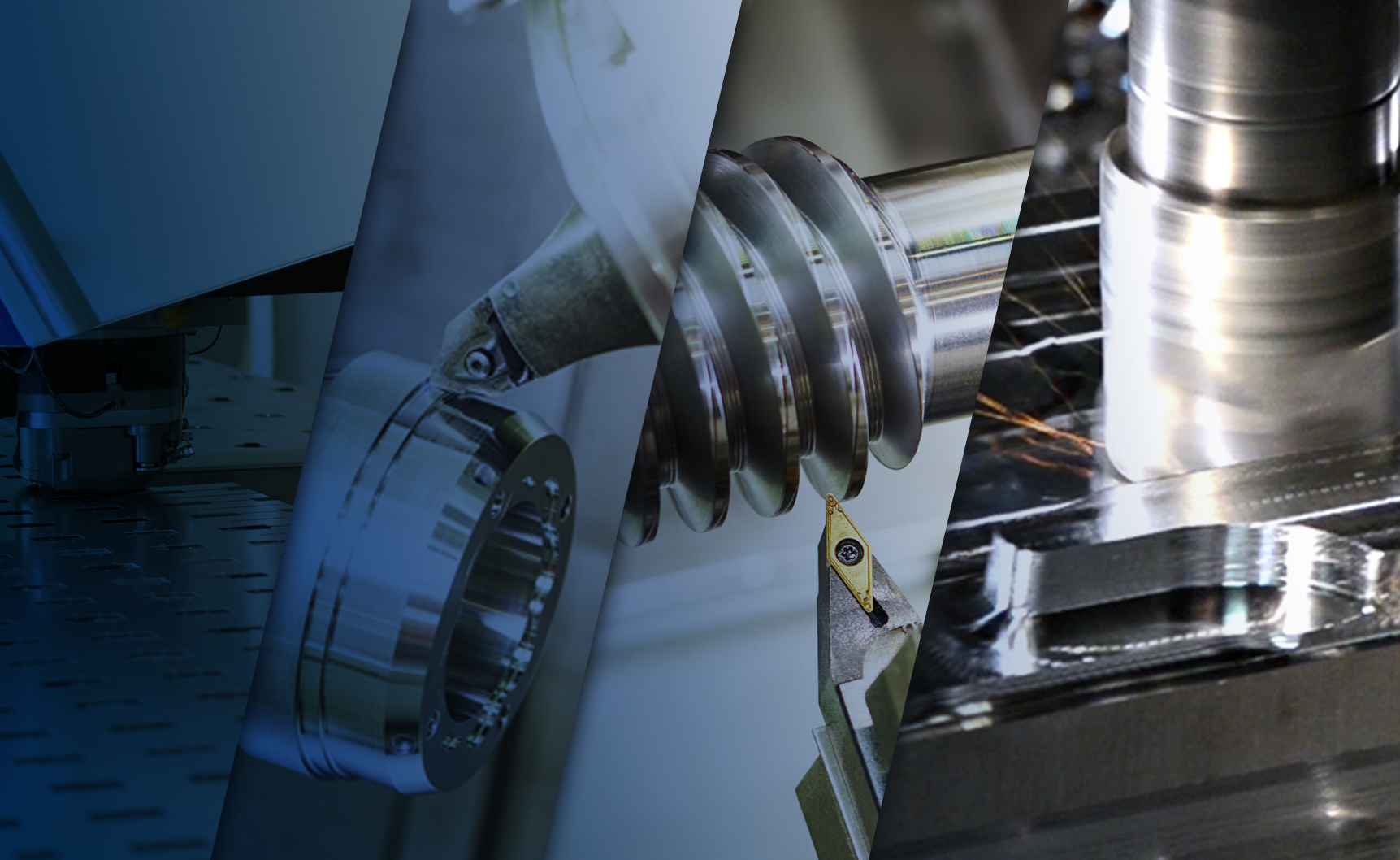

In this second article, dedicated to applications, we will make a passage on machines for chip removal, focusing attention on those belonging to the world of metal processing.

The great flexibility and modularity of the Power Family allows its use in various types of applications, those for milling, turning, drilling, cutting, deburring, tapping, bending, grinding, engraving, punching and slotting.

Recommended Numeric Controls

For simple machines, such as linear cutting, punching, bar feeders, drilling/tapping, controllers such as Power B, Power U and Power J+ are suitable, while for more complex machines, such as machining centres, lathes, grinding machines, etc. , Power I, Power D and Power A are indicated.

Specific metal working functions:

• G-code interpreter

• Open and fully customizable command library

• Tool correction

• Engraving and Emptying cycles

• Rototranslation of the axes

• Possibility of creating macros to build complex geometric profiles

• Jerk that may be changed in every different phases of the motion

• Sixth degree polynomial for RTCP head compensation

• Non-standard kinematics

• THC (Torch Height Control) which implies the management of the axes also from PLC.